Last Updated on January 29, 2024 by Pittalks

When performing a brake job on a vehicle, understanding the role of brake pistons is essential. Located within the brake calipers, these pistons are pivotal to the vehicle’s braking system, pressing the brake pads against the brake discs to facilitate deceleration. Constructed from various materials such as steel, aluminum, or rubber, brake pistons must occasionally be retracted to make room for new brake pads—a process typically requiring a specialized brake caliper tool.

In instances where such tools are unavailable, alternative methods can be employed to retract the brake piston. Common makeshift tools like screwdrivers, old channel locks, C-clamps, or caulk guns can be utilized with caution. These methods hinge on creating sufficient leverage or force to push the piston back without damaging the delicate parts of the brake system. When handling an inactive vehicle’s brakes, it is crucial to proceed with care to avoid compromising the system’s integrity and safety.

How to push brake caliper piston back without proper tool ?

If you do not know how to push back brake pistons without tool, you will get a thorough guide on how to do it. Different methods can help you complete this process. You will learn how to operate using a regular screwdriver, a C-clamp, old channel locks, and a twenty nine ounce smooth rod calk gun. Each method will have a clear procedure to help you push back your vehicle’s brake pistons with simple tools. Despite these methods being helpful in many ways, there are risks associated with them. These tools are not designed for the job. For this reason, each method will have its pro and cons.

Method 1: Using a regular screwdriver.

To use a screwdriver for retracting a brake piston:

- Inspect the rotors to see if they need to be replaced or resurfaced.

- Lift the car with a jack and secure it on a stand.

- Insert the flat blade of the screwdriver between the rotor and brake pad.

- Carefully create a gap, remove the pad, and then pry the piston back.

- After pushing the piston back, re-insert the pad and use the screwdriver to ensure the pistons are fully retracted.

Advantages:

- Simple and readily available tool.

- Able to perform the job alone.

- Straightforward procedure.

Disadvantages:

- Potential to damage the rotor if improperly done.

- May not always successfully push the piston back.

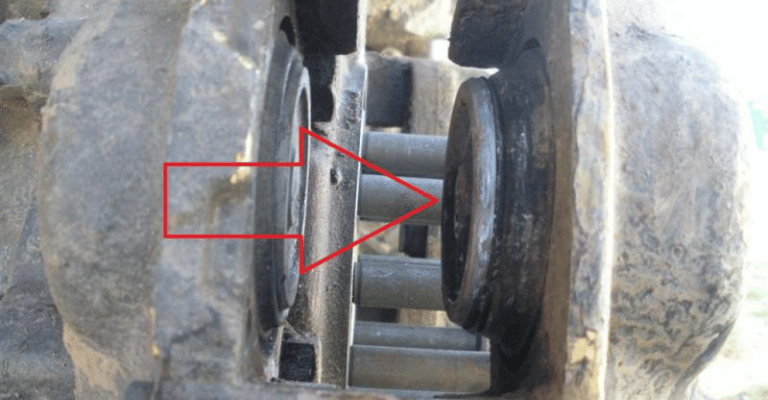

Method 2: Using an old channel locks

To use channel locks to retract the piston:

- Remove the car’s caliper clips.

- Position an old brake pad against the piston.

- Adjust the channel locks to fit around the brake pad and piston.

- Squeeze to compress the piston back into the caliper.

Advantages:

- Straightforward and quick to adjust for various piston sizes.

Disadvantages:

- May be difficult to keep the tool from spinning.

- May require substantial force.

Method 3. Using a C-clamp

To use a C-clamp to push back the piston:

- Choose an appropriately sized C-clamp, such as 6 inches, for your brake caliper.

- Position the C-clamp against the brake pad, ensuring the other end is on a flat surface of the caliper.

- Tighten the C-clamp gradually until the piston is retracted fully.

- If replacing brake pads, ensure the piston is compressed enough to accommodate new pads.

Advantages:

- Minimal effort required for piston retraction.

- Flexible to use with different caliper sizes.

- Quick and cost-effective.

Disadvantages:

- Can be tricky to find the right placement on the caliper.

- Risk of over-compressing the piston without realizing.

Method 4. Using a twenty nine ounce smooth rod caulk gun

To push back pistons with a caulk gun:

- Position the caulk gun against the brake pad.

- Use the trigger to apply force and retract the piston.

- Keep applying pressure until the piston has reached the desired location within the caliper.

Advantages:

- An economical tool alternative.

- Simpler method compared to some other tools.

Disadvantages:

- Might not be suitable for larger or heavier vehicles.

- It may not be effective in heavy vehicles such as trucks.

Reasons Why a Brake Caliper Piston Gets Stuck

Several situations can lead to a brake caliper piston getting stuck:

- Corrosion: Causes sticking due to roughened surfaces.

- Contaminants: Dirt and debris disrupt the piston’s movement.

- Brake Fluid Contamination: Results in sludge that hampers piston action.

- Seal Damage: Leaking fluid causes uneven pressure and piston sticking.

- Caliper Slide Pin Issues: Lack of lubrication or seized pins impact caliper and piston movement.

FAQs

Why can’t I push the caliper piston back?

There are several reasons why a caliper piston may not retract easily:

- Damaged mounting bolts: Neglect in lubricating the caliper bolts can lead to worn shielding boots, which results in compression difficulties for the caliper piston.

- Faulty pistons: Pistons may deform during use; if they do not slide back into position properly, this can hinder the brake fluid from creating the necessary pressure for retraction.

- Inactive vehicle: A vehicle that has been sitting idle for an extended period is prone to rust and corrosion on the caliper, preventing the piston from retracting smoothly.

Can you free a seized caliper piston?

To address a seized caliper piston:

- Lubrication and Cleaning: Gentle application of lubricant or rust penetrant can help loosen the piston.

- C-clamp Method: A C-clamp can often be used to carefully compress the seized piston back into the caliper.

- Compressed Air: Using compressed air can assist in loosening the piston, though this should be done with caution to avoid damage.

Note: It’s crucial to check the brake fluid level and condition during this process and to ensure that the bleeder valve is not clogged, which may also pose problems for piston movement.

Can a caliper Unseize itself?

Despite the slight possibility of a caliper freeing itself by vigorous pedal pumping, this is not a reliable solution and does not address the underlying problem. It’s important to perform regular inspections and maintenance on the brake system, including the master cylinder, brake lines, and ensuring there are no brake fluid leaks. Proper attention and care prevent the issues associated with seized pistons and the necessity for forceful interventions, which might cause more damage. In the case of persistent seizing:

- Bleeding the Brakes: This involves removing trapped air from the brake lines, which may help in freeing up the piston.

- Brake Fluid Flush: Sometimes, replacing old, contaminated brake fluid can improve the overall function of the brake system and aid in piston movement.

- Inspecting Brake Pipes: Ensuring that the brake pipes are free from obstruction or damage is another essential step.

If these measures do not resolve the issue, consulting a professional mechanic is advisable to prevent further damage to the brake system.

What methods are available for retracting a brake caliper piston if I don’t have access to any tools?

- Method 1: Using a steering wheel or auxiliary key can provide leverage to twist the piston back into the caliper.

- Method 2: For floating calipers, applying steady pressure with a pair of sturdy pliers or by hand if the piston is not too tight.

- Method 3: For screw-type pistons, using a screwdriver to turn the piston clockwise gently.

What steps should I follow if my brake caliper piston is stuck and won’t compress?

- Step 1: Clean around the piston and caliper to remove any debris.

- Step 2: Apply penetrating oil to the piston edges and let it sit.

- Step 3: Attempt compression again, using one of the non-tool methods if necessary.

- Step 4: If unsuccessful, seek professional assistance as the caliper may be damaged.

What precautions should I take when attempting to move the piston back into a brake caliper without a piston tool?

- Precaution 1: Ensure the master cylinder reservoir cap is removed or loosened to relieve pressure.

- Precaution 2: Avoid applying uneven force as it could damage the piston or caliper.

- Precaution 3: Always protect the piston surface from scratches and dents.

- Precaution 4: Do not disconnect the brake hose unless completely necessary to avoid introducing air into the system.